Inside factory

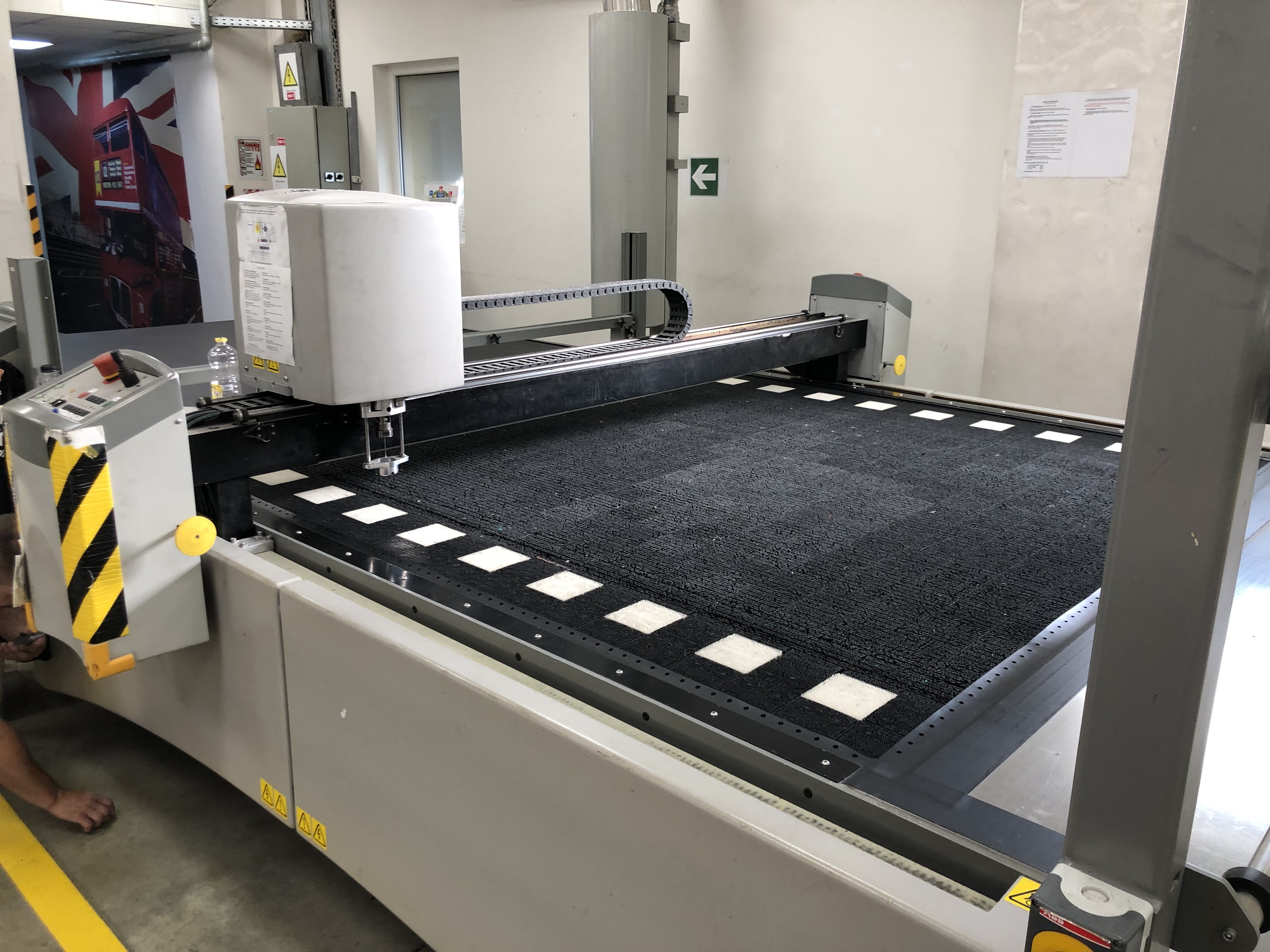

Gerber machine

Quick, accurate set-up and self-adjusting cutting intelligence allow operators to start cutting faster and with greater efficiency. Better productivity and workflow increase your output of cut parts and shorten lead times.

Layer machine

Compact, fast and reliable.

Metal detector

Detect metal particles in products transported on the conveyor belts.It is used either for quality inspection of the product being porcessed or as a protection of technology.

Pressing area

The pressing process influences the final garment appearance and hence the garment appeal. In garments industries there is a separate section for ironing the products. It is generally done by heated plates and electric irons in moist condition of garments.

Pressing area

Finishing and pressing machines contour the semifinished garment panels as well as finished garments by bringing down the fibres in the fabric to an elastic state and then deforming and setting them. It is also known as ironing

Storage area

We provide an ideal environment for storing raw material and textiles: clean, dark, cool, moderate humidity and reasonably dry place.

Fusing press

Comfort solution with intelligent control.This system designed for efficiency offers, in addition to comfortable operation for conducive working and effective workflow, the latest generation of controls.

Quality control

Quality could be termed as customers’ satisfaction; a good quality product means that it will fulfill all the purposes for which it has been produced. rQuality control in textile industry is the most important thing. So maintaining quality control in textile is a supreme priority task for Rexton Grup.

Garments warehouse

The smart management system of the warehouse help us to control finished products in stock, products delivered to customers and much more.Finished garment products need to be protected in appropriate conditions to ensure quality before being delivered to customers.